Fiorenzato F83 Burrs

Experience a superior grind with the Fiorenzato F83 grinder blade! This powerful 83mm diameter grinder blade offers a consistent grind for all your grinding needs.

More Information

Fiorenzato is the only company that is producing its own burrs using a material especially vetted for food preparation.

The materials used in the food processing industry must meet high requirements. They must in fact possess excellent mechanical properties and, at the same time, must guarantee maximum safety for the health protection .

Consequently, in order to ensure longer life and avoid contamination of food with metal ions, the steels used must have :

• high wear resistance

• high corrosion resistance

These are the characteristics of BÖHLER’s M340, tested and certified by AGES (Austrian Agency for Health and Food Safety)

Our burrs are internally produced by a number-controlled device, allowing for a manufacturing process that is all in one phase and thus ensuring high repeatability and very high standard for each and every grinder burr. A type of production that boasts four main advantages:

• repeatability

• excellent quality

• consistency

• excellent performances

Endurance Test

The endurance test involved simulating grinding in a coffee shop, about 32kg of coffee daily, with a total of 26 periodic checks and 2 taste tests (made with a Q-grader and SCA trainer). The test involved the parallel comparison of Fiorenzato F83 E grinds with the market standard burrs.

The technical analysis of the data collected focuses particularly on the following points:

1 - Variation in grinding times

2 - Shift in dispensing weights

3 - Variance of extraction times

4- Analysis of grinding adjustment ring nut versus 0 of the burrs.

5- Analysis of particulate curves with Mastersizer

6- Extraction analysis using refractometer.

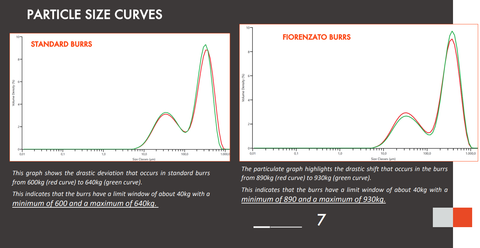

As a result of this test and data analysis, we can confirm that the limit window of the standand burrs is in the proximity of 600 kg.

Much better, in terms of durability, are the Fiorenzato burrs, which reach the limit window in the near 900 kg. Variations in durability, albeit slight, may occur depending on the blend of coffee used.

When analyzing the burrs in the production environment, Fiorenzato's mechanical machining processes prove to be successful compared to standard market burrs, especially by virtue of the fact that the tooth cutting edge is not brushed or regained by sandblasting.

The use of Böhler M340 steel gives added value not only in compliance with food regulations, but also in terms of performance.

WE CAN CONCLUDE BY SAYING THAT THE BURRS MANUFACTURED IN FIORENZATO HAVE A 50% HIGHER DURABILITY RATE THAN OTHER BURRS ON THE MARKET.